As ship sizes continue raise, ports struggle maintaining and hopefully increasing port operations productivity. The large number of berths, cranes, warehouses and labors they need to handle make the operations planning particularly complex.

Photo by Olga Subach on Unsplash

Good planning of port operations reduces waiting time for ships, increasing customer satisfaction and port productivity thus gaining a competitive advantage over its neighboring ports in the region. A ship that is delayed because there is no berth for it may miss its scheduled port call to stowage cargo and create a cascade of delays for other ships.

Keeping quay crane productive is a typical focus in the profitability of the operations. Lower rates of quay crane transfer operations causes delay in ship and container yard operation. Which causes difficulty for recipients and delivery activities. Indirectly, quay crane moves dictates the berth utilization, turn-around time of ships and then the overall port performance.

Image – The geography of transport systems, Rodrigue 2020

Port Calling

The process of accepting a new service (i.e. a ship arrival) at the terminals begins with the offer by the shipping lines. The shipping line provides the port with the following information:

- Number of movements expected

- Service frequency: weekly or biweekly

- Day – Expected time of arrival of the service, or time window

- Physical characteristics of the type ship that will provide the service

Based on the information provided by the shipping company, and the current assignment of services to terminals and berths to ships, the commercial area, supported by the operations area, analyzes whether or not it is feasible to serve this service in port facilities.

The port may negotiate minor changes in the time window of the service. In case the service is very important for the port, the port could negotiate minor changes with the already established services.

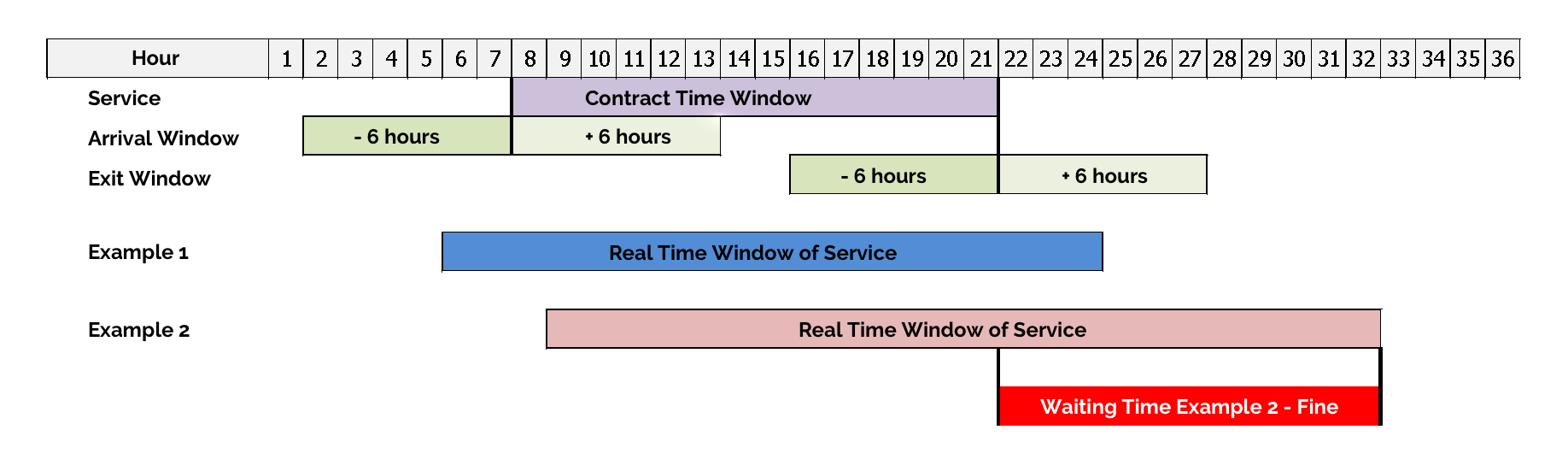

The waiting time is the difference between the time of departure from the service window and the actual time of departure from service when the latter is greater than the time of departure from the service window plus six hours. In the figure, it can be clearly seen how the waiting times are calculated with respect to the time window.

Port Logistics

The ship service operation begins the instant the ship arrives at the buoys point.

Berthing

A pilot from a city piloting company leads the ship from the buoys point to the to the location where the berthing maneuver begins, taking an average of 3/4 hours. Next comes the Berthing operation consisting of parking of the ship in the section of the berth that has been assigned to it. This activity takes on average 3/4 hours. Next is the Preparation of the Service / Ship, which consists of performing the documentation review and its initial inspection. Approximately 1 1/2 hours are required for its development.

Loading and unloading

For the Loading and Unloading operation, the ship needs to have the necessary number of cranes, for the time necessary, to comply with the minimum productivity of movements committed to the shipping line that allows the ship to set sail respecting the time window stipulated in the commercial negotiation. All necessary activities are carried out for the movement of containers to and from the port’s storage yards.

Zarpe

Then comes the Closing activity, which in spirit and time is similar to the Preparation activity and takes on average 1/2 hours. Finally the ship can set sail. Zarpe activity takes an average of 1/2 hours.

Berthing and scheduling quay cranes

The assignment of ships to berths needs to take into consideration the physical characteristics of the ship (length, width, depth) as well as the operational limitations of cranes (height, reach, range of operation, movements per hour).

The goals are leveraging optimization capabilities to tackle the complexity of the different interconnected sub-systems.

- Better Service. Shorter waiting and queuing times have a positive impact on port efficiency and attracting more shipping companies to berth at the port.

- Better Revenue. Increases cargo throughput. Reduction of congestion (traffic jam) during load / discharge operations across different ships and quay cranes.

- Reduce Cost. Improves infrastructure & manpower utilisation.

The optimization of the port planning operations are usually decomposed into the Berth allocation problem (BAP), Quay crane assignment problem (QCAP), Quay crane scheduling problem (QCSP) and Port yard storage optimization problem (PYSOP) working simultaneously.

- BAP assigns the available berths (where, when & how long) to the arriving ships.

- QCAP assigns the number of quay cranes and which ones to serve each berthing ship (of different sizes) during the planning horizon.

- QCSP sequences the quay cranes handling order to stowage (un/loading) containers.

- PYSOP allocates space to cargo in a designated yard.

Main components in a port

The main components in the port operations to be optimized are

Services

They are the routes or itineraries that offer shipping lines, sold by container transportation companies. A service can be served by different ships from different shipping lines but with similar operational characteristics. Some services are regular, others irregular.

Berths

Berths are the places where the ships are parked to carry out the loading and unloading operations.

Photo by Alex Duffy on Unsplash

The main parameters that characterize the operation of a berth are

- length & depth

- maximum weight tolerance

Ships

Ships are the entities that transport the cargo. Their main characteristics are

- empty weight

- length

- width

- draft

Photo by Andrey Sharpilo on Unsplash

Some ships have their own cranes with which they load and unload containers. In the event that these cranes are used, they will be port operators who will handle or manipulate them. Conversely some quay cranes cannot be assigned to certain ships because of their height or because they conflict with existing cranes on ships, creating risks of collision.

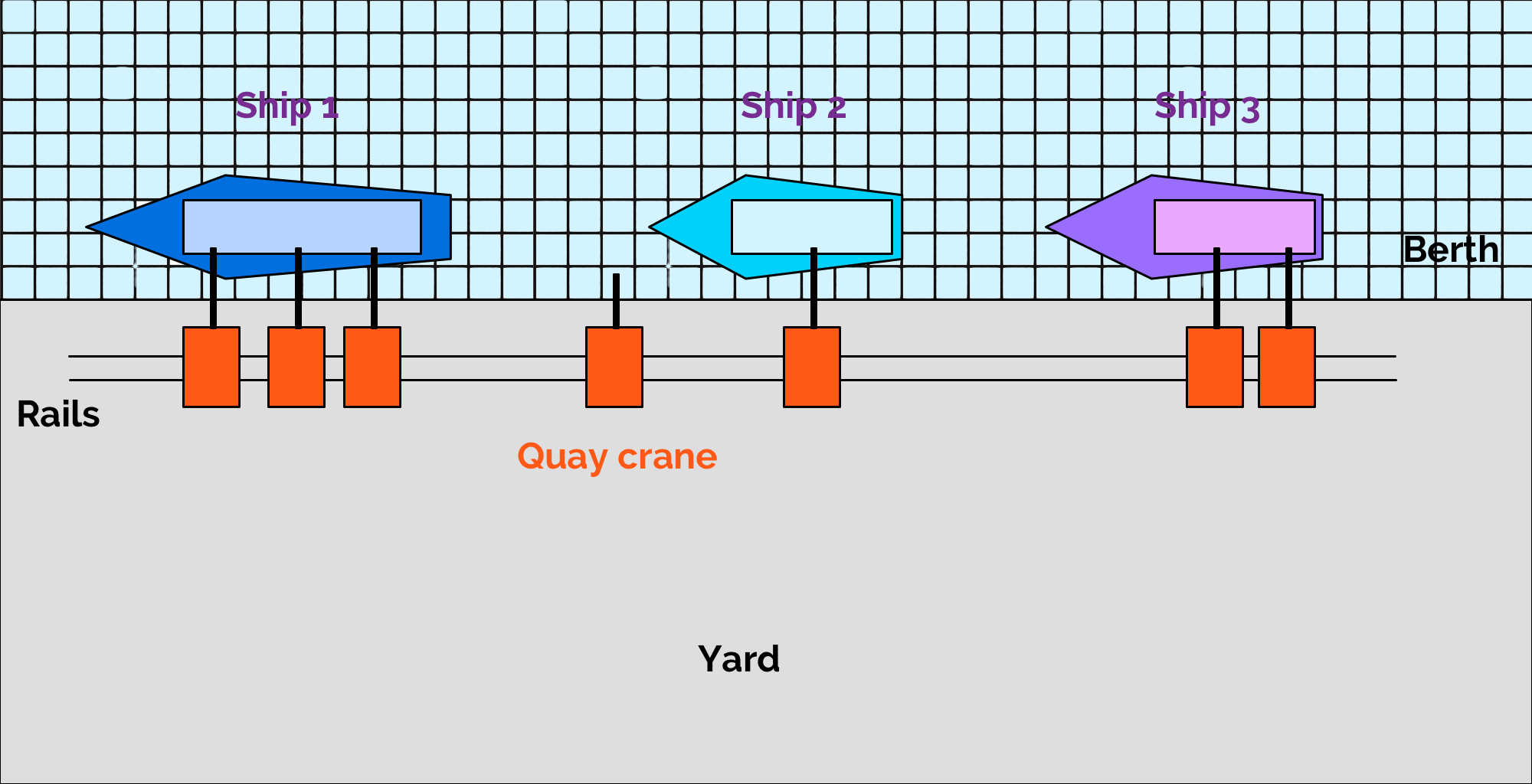

Quay Cranes

Quay cranes are in charge of the loading and unloading of the containers between the ship and the berth floor. Their main characteristics are

- lifting height

- seaside range

- effective range of length

Photo by Jacob Meissner on Unsplash

Cranes are installed in a single rail along the berth, hence cranes cannot cross when attending ships.

Yard

Yards are the port facility where containers are stored before they are loaded onto a ship or after they have been discharged from a ship.

- import containers arrive in large batches which are brought in by ships. They will be temporarily stored in the yard until being retrieved by local customers.

- export containers are brought in by customers and accumulated in the storage yard until their destination ship arrives.

- transshipment containers are temporarily stored in the yard after being unloaded from a ship, waiting to be loaded on another ship

Photo by Chuttersnap on Unsplash

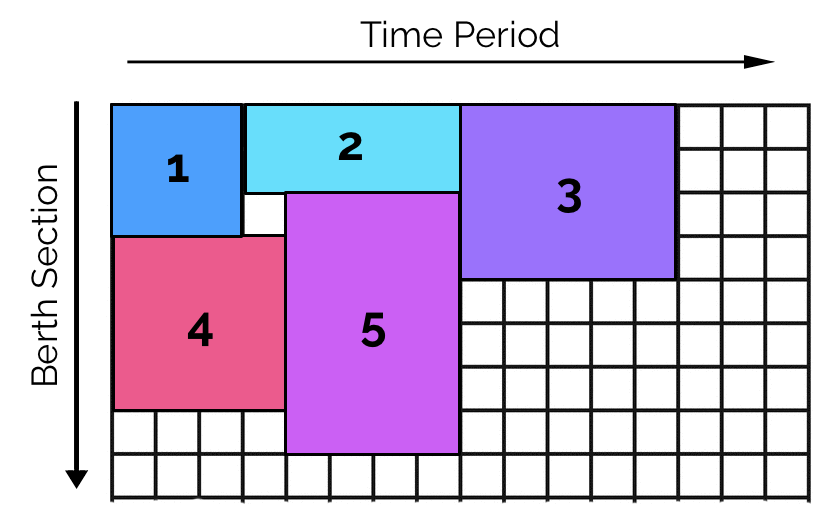

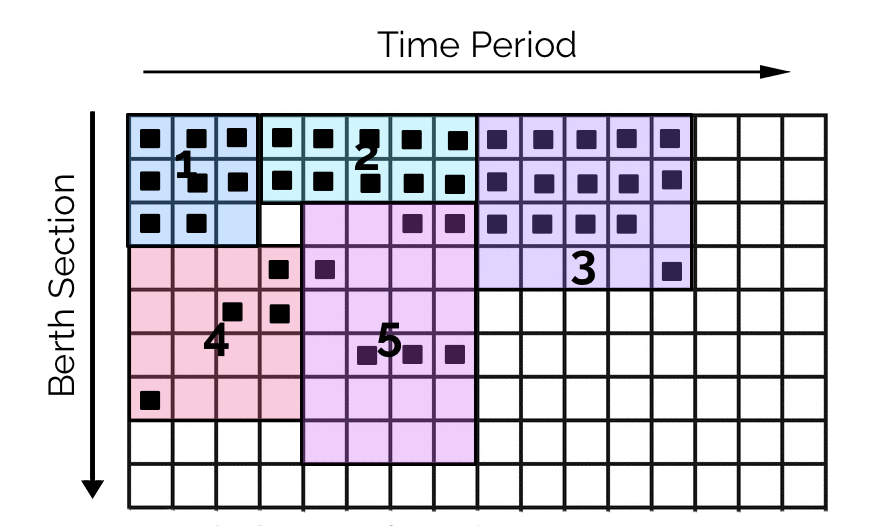

The berth allocation problem (BAP)

The berth allocation problem assigns arriving ships to a section of the berth during enough time for the loading and unloading operations to take place.

The duration of the berthing is considered fixed (based on historical averages). As a result, the problem reduces to a variant of the rectangle packing problem.

The ships earliest arrival and latest release times translate into bounds on the time period axis. While compatibility between ships and berth sections (due to draft or weight limitations for instance) translate into forbidden positions for the rectangles.

The quay crane scheduling problem (QCSP)

The quay crane scheduling problem assigns cranes to ships / berth sections for loading and unloading containers.

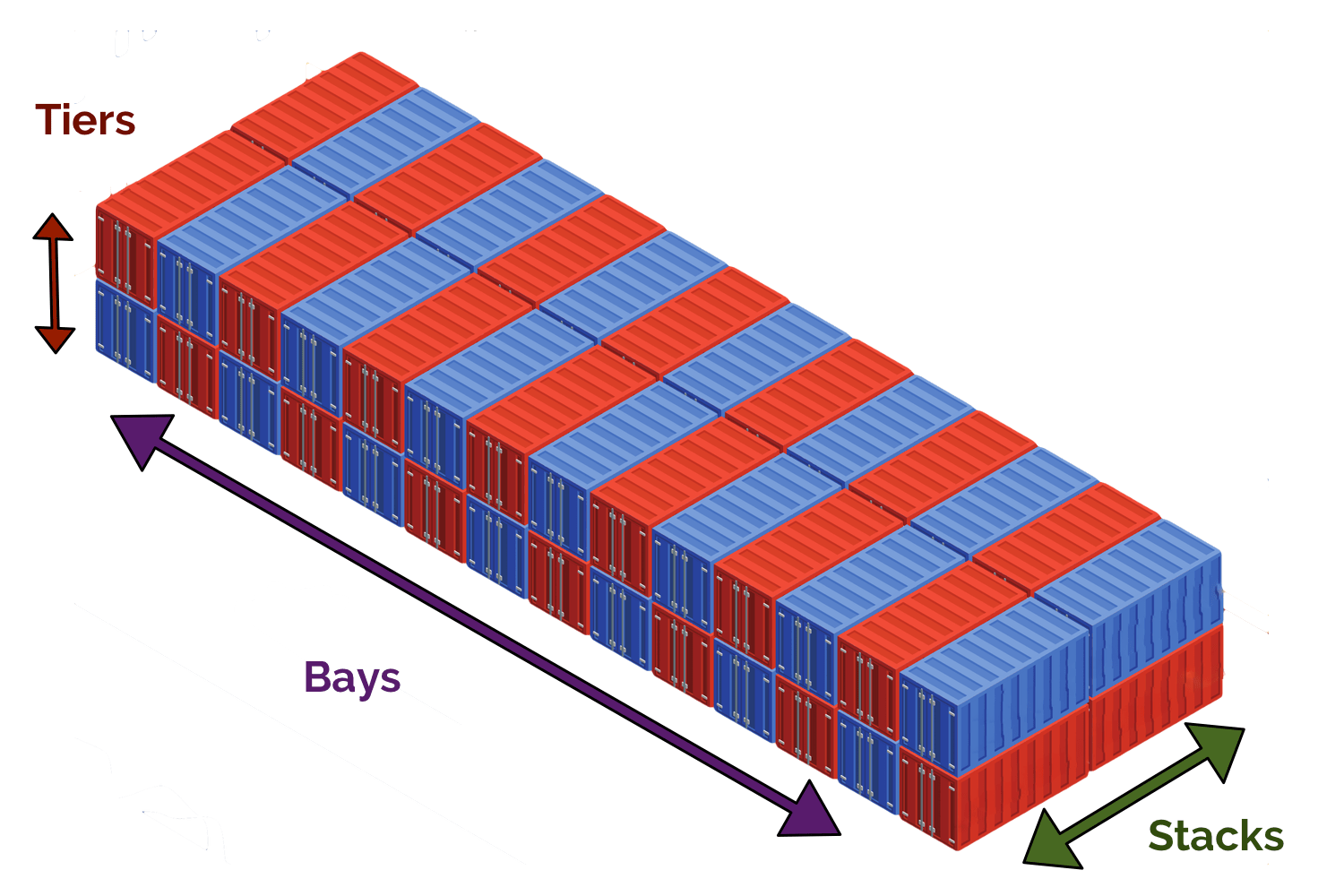

Container movements are grouped into holds (batches) in order to make the problem easier to tackle. Therefore each ship is associated with a number of holds that need to be assigned to a crane. Each berth is divided into bays where the crane has to position.

Quay cranes are mounted on a single rail which prevents them to crossing. Because of this fact, and depending on the policy of the port, cranes can be blocked on a hold (meaning a single crane will execute all the container movements in that hold) or shifted across holds. Depending on the length of the holds, moving the cranes along the berth may be negligible or not.

The crane scheduling problem can be seen as a scheduling problem with side constraints to prevent crossing of cranes.

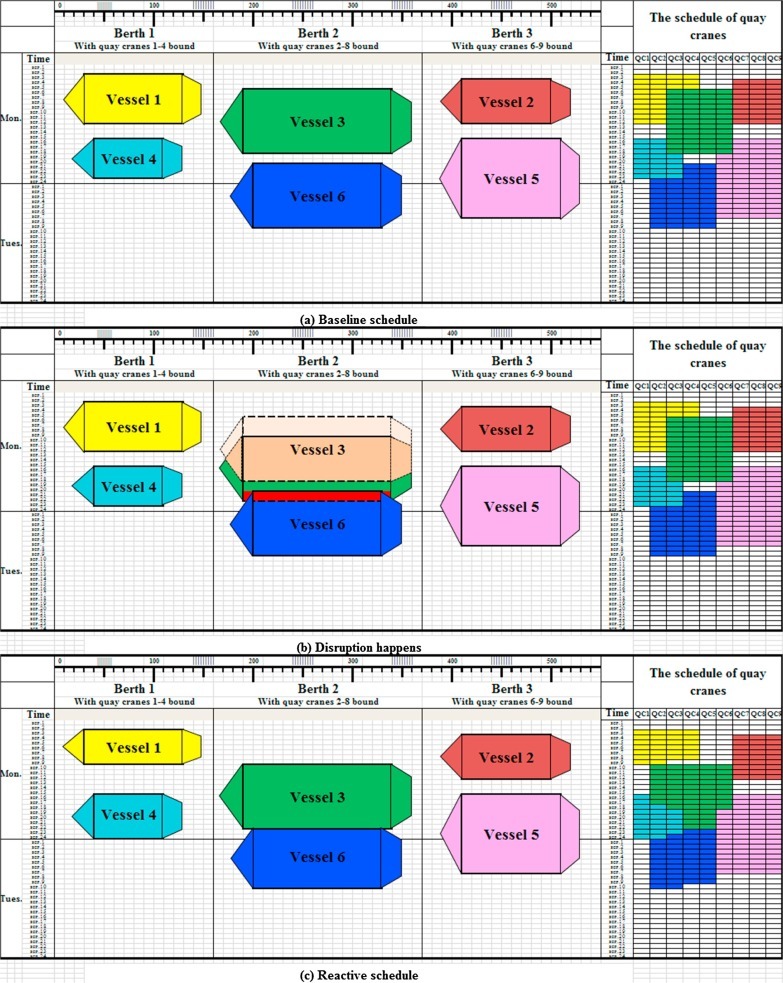

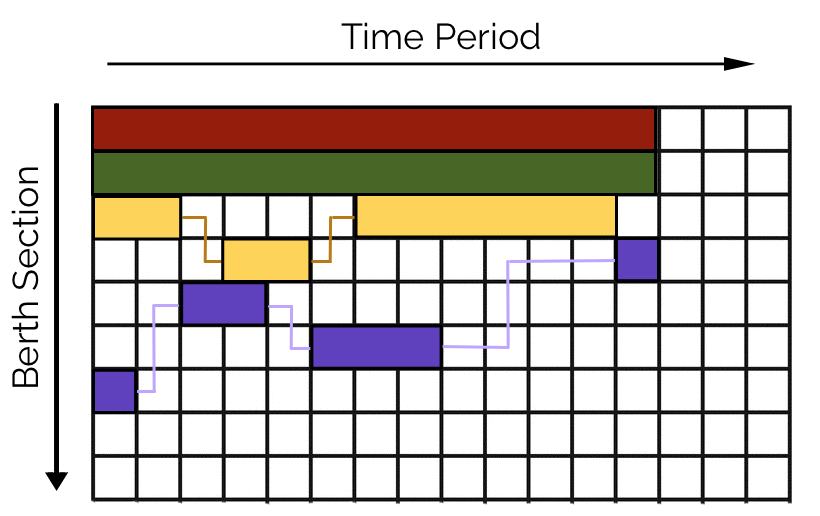

The berth and quay crane scheduling problem (BQCSP)

The combined berth and quay scheduling problem considers simultaneously the allocation of the ships to the berth, the fact that for each boat a given number of holds need to be assigned to cranes and the number of cranes available.

Under the assumption that all holds are the same length, don’t interfere with each other, crane positioning time is negligible and cranes can be shifted, the problem can be represented as a rectangle packing problem in which the width of the rectangle is not fixed. Instead, the rectangle will be as long as necessary for all holds to be assigned to cranes. At the same time the number of simultaneous holds is limited.

Various simplifying assumptions can be relaxed

- holds of different duration

- specific bays for each hold

- positioning time for cranes

- compatibility with some cranes and holds / ships

- avoidance or forbidding of crane shifting

As more assumptions are relaxed, the problem progressively turns into a complex scheduling problem with a spatial resource.

The port yard storage optimization problem (PYSOP)

After being unloaded from a ship, containers move to the yard for temporary storage. Due to storage space limitations, containers need to be stacked.

Stacking containers in a way that minimizes the number of operations required to retrieve them while fitting in the available space is the port yard storage optimization problem (PYCSP). The sub-problem consisting in scheduling the movements of the cranes to retrieve a certain group of containers is the yard crane scheduling problem (YCSP). While the sub-problem consisting of finding the movements needed to retrieve a container from a stack is the container relocation problem (CRP)

Ideally yard management should be also synchronized with the schedule of ship arrivals and departures to optimize the accessibility of the containers based on the with the precedence relationships created by the berthing schedule.

Conclusion

Port operations are complex. While ideally all operations from berthing to yard management should be synchronized, modeling and solving difficulties have driven optimization practitioners to divide the operations into multiple independent slices.

As modeling and optimization engines improve, some of those optimization problems can be considered in conjunction, resulting in better overall solutions and higher productivity for the port.

In a future post, we will model the different problems separately and in conjunction.